- Concrete Sealer

- Comparison Chart of Concrete Sealers

- Buying Tips for Concrete Sealer Products

- Concrete Sealer Reviews: Sealer products other contractors use and recommend

- Common Questions about Concrete Sealers

- How to Remove Concrete Sealer

- Types of Sealers

- Acrylic Sealers

- Epoxy Sealers

- Penetrating Sealers

- Polyurethane Sealers

- Polyaspartic Sealers

- Application Surface

- Driveway Sealer

- Patio Sealer

- Pool Deck Sealer

- Sealers for Stamped Concrete

- Concrete Floor Sealers

- Concrete Countertop Sealers

- Pool Deck Sealer

- Exposed Aggregate Sealer

Concrete Sealers for Indoor and Outdoor Surfaces

A concrete sealer is essential for protecting surfaces from water damage caused by freeze/thaw cycles, stains from dirt, deicing salts, oil and other contaminants, and much more. So, if you’ve just installed the decorative concrete masterpiece of your dreams, make sure it gets sealed.

Top 10 Sealer Questions

Get answers to frequently asked sealer questions from a technical expert.

Top 10 Sealer Questions

Get answers to frequently asked sealer questions from a technical expert.

Compare Sealer Types

Use this chart to quickly decide which sealer type you should buy for your project.

Compare Sealer Types

Use this chart to quickly decide which sealer type you should buy for your project.

Removing Concrete Sealers

Learn how chemical strippers work, how to choose the best one, and what precautions to take when using them.

Removing Concrete Sealers

Learn how chemical strippers work, how to choose the best one, and what precautions to take when using them.

Whether it’s a pattern-stamped pool deck or patio, an interlocking paver driveway, an acid-stained floor, or an exposed-aggregate walkway, a good sealer will keep it looking spectacular for many years to come while extending its service life. And even if the surface begins to show wear after years of exposure to traffic and the environment, you can often restore its original beauty with a good cleaning and fresh sealer application.

Find contractors offering concrete sealing near me.

On this page:

Concrete Floor Sealer

Exterior Concrete Sealer

Concrete Countertop Sealers

Concrete Sealer Reviews

D-One Penetrating Sealer

Non-yellowing, low sheen, good adhesion

D-One Penetrating Sealer

Non-yellowing, low sheen, good adhesion

Deep Penetrating Sealer

RadonSeal - Waterproofs & strengthens.

Deep Penetrating Sealer

RadonSeal - Waterproofs & strengthens.

Clear-Seal by Increte Systems

Seals and protects decorative surfaces.

Clear-Seal by Increte Systems

Seals and protects decorative surfaces.

Heavy Duty Oil & Stain Protector

TS210 - 4 gal. kit ($439.95)

Heavy Duty Oil & Stain Protector

TS210 - 4 gal. kit ($439.95)

Colored Concrete Sealer X-4

High gloss finish available in 20 colors

Colored Concrete Sealer X-4

High gloss finish available in 20 colors

Gem-Guard SB

Penetrating sealer that protects against salt damage

Gem-Guard SB

Penetrating sealer that protects against salt damage

Decorative Sealers

Reactive and penetrating formulas in various levels of gloss.

Decorative Sealers

Reactive and penetrating formulas in various levels of gloss.

Water Repellent Penetrating

Sealer for driveways, parking structures, plazas, walkways & more.

Water Repellent Penetrating

Sealer for driveways, parking structures, plazas, walkways & more.

Clear Acrylic Concrete Sealer

$219.30 (5 gal.)

Clear Acrylic Concrete Sealer

$219.30 (5 gal.)

WHAT'S THE BEST CONCRETE FLOOR SEALER?

Concrete is an incredibly durable flooring choice, especially when properly sealed. Whether for a commercial or residential property, a basement or a garage, a concrete floor sealer is an easy and affordable way to ensure the surface will look its best and function well for years.

A good concrete floor sealer will:

- Prolong the life of a floor

- Enrich and preserve its appearance

- Provide resistance to scuffs and stains

- Prevent moisture problems

Film-forming sealers, either epoxy or acrylic, are most often used for indoor flooring. Epoxy concrete sealers are the most durable, making them good for sealing garage floors and high-traffic retail environments. Softer acrylic sealers, which require a sacrificial floor wax, are more affordable and popular for residential concrete floors, including basements. When working indoors, it's safest to apply a water-based sealer, because they don’t contain harmful fumes from VOCs.

WHAT'S THE BEST OUTDOOR CONCRETE SEALER?

Sealing outdoor concrete surfaces is an essential part of hardscape maintenance. Concrete sealer is a lot like car wax-many people go without and then regret it when the paint peels. Sealer may not seem necessary at first, but after a few years of exposure to weather and use concrete can become discolored, stained or even flaky.

A combination of spraying and rolling is being used to seal a stamped concrete driveway.

Decorative Concrete Institute in Temple, GA

A concrete driveway or patio sealer will protect against:

- Oil stains

- Tire marks

- Deicing salts

- Yellowing or fading

- Water damage

- Dirt, mud and mold

- Lawn care chemicals

All types of exterior concrete should be sealed including plain concrete, stamped concrete, stained concrete, integrally colored concrete, exposed aggregate, stenciled concrete, engraved concrete and overlays. Each surface lends itself to unique needs when it comes to a sealer. For more information, check out these in-depth resources:

The best concrete sealer for a driveway, patio, pool deck or walkway is UV resistant, breathable, and slip resistant, even when wet. When a good concrete sealant is used, maintenance is easy—wash the driveway or patio with soap and water, or a degreaser designed for use on cement, and apply a fresh coat of sealer about every three years.

Outdoors a penetrating concrete sealer is usually better than a film-forming product for safety reasons, but also because the end result will last longer and looks more realistic and natural, especially when sealing stamped concrete.

WHAT'S THE BEST SEALER FOR CONCRETE COUNTERTOPS?

Sealing is the last, but most important, step when installing concrete countertops in a kitchen or bathroom. A waterproof concrete countertop sealer will prevent food stains as well as scratches.

The best sealers for countertops are:

- Heavy-duty

- Food-safe

- Colorless

- Non-yellowing

- Heat and scratch resistant

- Low-odor, with zero VOCs

Countertop sealers come in varying sheen levels, from matte to high gloss. If you want to be able to use your countertop immediately, you can opt for a fast-curing sealer. For extra protection and shine, some countertop installers will apply a food-safe finishing wax over the concrete sealer.

CONCRETE SEALER REVIEWS

The concrete sealers with the best reviews tend to be professional grade, not the type you can buy at your local home-improvement store. Professional grade sealers can be ordered online through specialized companies, or purchased at a local concrete supply store.

Top reasons for a good concrete sealer review:

- Easy to apply

- Good coverage rates

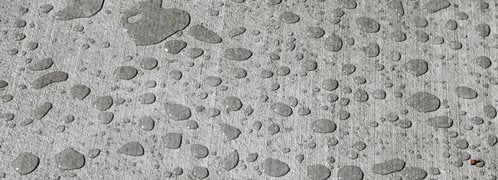

- Water beads up nicely

- Dries quickly

- Low odor

- Doesn’t change the color of the concrete

- Resists scratches

- Lasts a longtime

- Prevents flaking from freeze-thaw damage

SEALING NEW CONCRETE VS. SEALING OLD CONCRETE

Most sealers are best applied when the concrete has been allowed to fully cure for at least 28 days. However, there are cure and seal products available that can be applied as soon as the concrete is strong enough to support the weight of a person.

If you’d like to seal fresh concrete soon after pouring, select a sealer that contains a curing compound. Make sure to wait until all the bleed water has evaporated from the surface of the concrete before applying a cure and seal.

Sealing can be a great way to restore the appearance of old concrete. Existing concrete can be sealed or resealed at any time. Some manufacturers make sealers specifically formulated for older, more porous concrete.

If there is already a sealer present, it may need to be removed. Check with the sealer manufacturer to see if you can seal over the top of the existing sealer. If the concrete is unsealed, all it needs is a thorough cleaning before applying sealer. You may also wish to fill any significant cracks prior to sealing.

WILL SEALING CONCRETE CHANGE ITS APPEARANCE?

This depends on what type of concrete sealer you choose (use this concrete sealer comparison chart to compare your options). The main purpose of any sealer is protection; however, some also enhance the color or gloss of the concrete. If you don’t want your concrete to look different, a clear concrete sealer that penetrates beyond the surface will not change its appearance.

Sealer Color: Colored concrete sealers are tinted to add color to plain concrete or augment the color of stained concrete. Additionally, some sealers enhance, or deepen the color of concrete that has been integrally colored or stained.

Sealer Gloss: Sealers come in different gloss levels, ranging from a flat natural finish to a high-gloss, reflective finish. Wet look concrete sealers have the highest solids content, giving the concrete the glossy look some people desire. Sealers with high-gloss often need grit added to make them slip-resistant.

FILM-FORMING VS. PENETRATING SEALERS

Concrete Sealers - Sealer Selection Tips

Time: 04:34

There are two main types of concrete sealers: film-forming sealers and penetrating sealers.

Film-forming sealers include acrylics, epoxies, and urethanes that form a coating on the surface of the concrete. Film-forming sealers, especially acrylics, are more susceptible to wear and will need to be reapplied frequently. This type of sealer is sometimes referred to as a topical concrete sealer or a coating.

Tip: Choose a film-forming sealer if you want a wet look or high gloss finish that enhances the color of your concrete.

Penetrating sealers include silanes, siloxanes, silicates and siliconates that penetrate into the concrete to form a chemical barrier. Penetrating sealers have a long lifespan and are a great choice for exterior applications. They don’t peel, delaminate or wear away. This type of sealer is sometimes referred to as an impregnating concrete sealer.

Tip: Choose a penetrating sealer if you prefer a natural finish that will not change the look of your concrete.

HOW MUCH SEALER DO I NEED?

To determine how much sealer you’ll need for your concrete you need to know these things:

- Coverage rate

- Square feet

- How many coats are required

For example, if the sealer you are using will cover 100 square feet per gallon and your patio is 200 square feet, you will need two gallons. For sealers requiring two coats, they typically cover twice as much on the second application. So in this scenario that would be 200 square feet, meaning you would only need one additional gallon for the second coat, making it three gallons in total.

Coverage rates will vary depending on the porosity of your concrete. Typically, older concrete is more porous and may require extra sealer.

It is always a good idea to have more sealer on hand than you think is necessary. You don’t want to run out before the job is complete. Stopping and starting sealer application can cause appearance and performance problems.

CONCRETE SEALER APPLICATION TIPS

Applying a sealer to concrete is a fairly simple and fast process (learn more about how to apply concrete sealer). Most are applied in a similar way, but always check the instructions on the specific sealer you are using before getting started.

Sealer success tips:

- The surface must be clean and dry to ensure good adhesion

- Allow new concrete to cure fully prior to sealing

- Seal concrete when the weather is dry and above 50°

- Always apply sealer in thin layers

- Two coats will provide the best protection

- Solvent-based sealers are best spray applied

- Water-based sealers are best applied by roller

- If you have textured concrete (broom finish or stamped), sealer may pool if applied too thickly

Applying concrete sealer is something that many homeowners take on as a DIY project. If you choose to do so make sure you have the appropriate protective gear and equipment needed. Also do plenty of research about the process and follow the instructions included with your sealer carefully.

HOW LONG DOES IT TAKE TO SEAL CONCRETE?

Sealing concrete is a fast process that can be completed in a single day. If the sealer you’re using requires two coats, you may have to wait a specified amount of time before applying the second coat. However, some sealers can be applied wet-on-wet, which means there is no downtime.

Here are approximate dry times for the various sealer types:

- Acrylics dry fastest, dry to the touch within one hour

- Penetrating sealers are dry to the touch in about 3 hours and ready for traffic in 6-12

- Epoxies and urethanes take the longest to dry, up to 48 hours

WHEN SHOULD CONCRETE BE RESEALED?

Most concrete should be resealed every 1 to 3 years. However, this will depend on the type of sealer used, the amount of abuse it is exposed to and so forth.

Signs that you may need to reseal:

- Water no longer beads on the surface, but instead soaks into the concrete

- The sealer appears scratched, worn, dull or dirty

How long concrete sealers last:

- Penetrating sealers containing silicate, silane, or siloxane last longest, sometimes a lifetime

- Soft acrylic coatings wear the fastest, needing reapplication every 1 to 3 years

- Epoxies, polyurethanes and polyaspartics are much harder than acrylics lasting 5-10 years

WHY IS IT IMPORTANT THAT A SEALER IS BREATHABLE?

Concrete is porous, which means air and water can pass through from one side to the other. If a sealer isn’t breathable, this moisture would become trapped and cause problems. During the winter, trapped moisture can freeze and expand within the concrete, leading to cracks or other surface damage such as spalling or efflorescence.

The best concrete sealers allow moisture and air to escape, while still providing protection. Most manufacturers describe this quality as breathability and recognize that it is especially important when sealing outdoor surfaces. Penetrating sealers and acrylics offer the best breathability.

COMMON CONCRETE SEALER PROBLEMS

Sometimes concrete sealers fail. The most common reason for sealer issues is improper application.

Concrete sealer problems and their causes:

- Bubbles - caused by applying sealer too thickly or over-rolling

- Discoloration - white or cloudy efflorescence-like markings caused by trapped moisture

- Peeling - caused by moisture-vapor, contamination or over-application of the sealer

- Streaks/Lines - caused by the sealer drying too quickly during application

In some cases, these problems can be fixed by applying a fresh coat of sealer to the concrete, other times the existing sealer may need to be stripped first to start fresh.

IS CONCRETE SEALER TOXIC?

All concrete sealers should be handled with caution. During application, toxic fumes can be bothersome and the sealer can be a skin or eye irritant.

Sealer safety tips:

- Open doors and windows for good ventilation

- Wear a mask or respirator

- Wear long sleeves and pants

- Wear gloves, good shoes and eye protection

- Wash well after applying sealer

Some sealers contain VOCs (volatile organic compounds) that are released into the air during application and at a slower rate after the sealer has dried. Recent federal and local regulations have set limits for VOC content.

Newer water-based sealers are less harsh and contain lower amounts of VOCs. Many are also environmentally friendly and qualify for LEED points.

If you are a contractor who applies sealer on a regular basis, take precautions to prevent breathing in an excessive amount of fumes.