- Prepackaged Countertop Mixes

- Countertop Mix Reviews

- Related Information

- Concrete countertop supplies

- Understanding concrete countertops: Pricing, colors, edge details, and more

- Glossary of concrete countertop terms

- Going green with concrete countertops

- Concrete countertops photo gallery

- Outrageous concrete countertop projects

- How-to books & DVDs for concrete countertops

A Definitive Polisher for Concrete

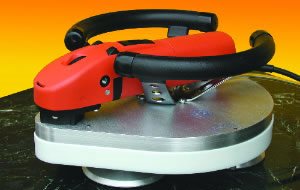

The DS 301 Planetary Polisher from a Stone Equipment and Supply HouseFind Concrete Countertop Tools & Suppliers

If you make concrete countertops, pour concrete floors or steps, the DS 301 Planetary Polisher is for you. This hand-held polishing tool is unique in the industry, accomplishing flat, smooth concrete surfaces quickly. It is a true planetary polisher. With three small heads mounted on a large wheel, it moves like the earth around the sun the small heads spinning in one direction and the large head traveling in the opposite. What makes this polisher unique is that the heads are powered from the side rather than from the centeran improvement in polishers that is the genius of its creator, Dennis Stoscher, co-owner of Intertool and its sister company, Leitch & Co.

Stoscher is an electrical engineer and very creative. As Stoscher became more familiar with the stone industry, he saw a need for tools to use in small areas to smooth and polish stone. The only tool for polishing available at the time was a large overhead piece of equipment that required transportation of the stone to the polisher. There was no tool to take to the field, which could perform the same functions of polishing and/or detail work. Smaller jobs such as coffee tables or finishing stairs were almost impossible to accomplish and still keep surfaces flat and level. One of Stoschers early attempts at a portable tool involved converting a carpet shampoo machine from the maintenance industry by attaching diamond pads for grinding and polishing large surfaces. He introduced the smaller sized hand-held DS 300 (now 301 Planetary Polisher) as a tool for the stone industry in the early 1990s. It was first used by the monument trade, and then for dimensional stone products.

Application to concreteBuddy Rhodes of Buddy Rhodes Studios, a Northern California decorative concrete manufacturer was one of the first to inquire about tools from the stone industry to polish concrete. When the concrete countertop industry started to blossom in the late 1990s, the advantages of the DS301 made it the logical choice for grinding and polishing surfaces.

THE 301 PLANETARY POLISHER ADVANTAGE

-

It is hand-held and easy to use.

-

It grinds down, hones and polishes fast and flat without swirls.

-

It finishes to within 1/4 inch of walls.

-

It utilizes a random orbit technology, reducing the possibility of creating uneven surfaces and gouge marks in finished surfaces.

-

The tool has a low profile, only 3 1/2 inches and goes underneath small areas like a toe kick.

-

The hand held polisher and floor machine (mentioned later) comes with a vacuum attachment for dust control.

-

It finishes countertops wet or dry. Generally, a wet grind is preferred for diamond polishing concrete, but sometimes that is not possible, and the tool grinds dry.

-

It is a multi-use tool. Use it on Granite, Corian, engineered stone, or concrete surfaces with diamond polishing pads. Or, you can attach sanding pads and use it on wood.

-

The recent 301 Model, which Intertool issued last year, made an improvement on the one shortfall cited by users--the noise level. Now, with improved mechanics, the tool is quieter.

DS 301 with cowl. (Included as an option use.) Shows the cowl referred to in the bullets section for dust control.

Keys to the Effectiveness of the 301 Planetary Polisher:

-

Variable Speed

-

Diamond Pads

-

Matching Hardness of the Matrix

Variable SpeedMost Planetary gears are center driven. However, a center gear reduces the possible RPM or speed of the polisher. A side driven gear provides greater torque, thus faster speeds. Different diamond grit pads work best at different RPMs. Coarser grit sizes are more effective at higher speeds, while finer grit pads do better at slower speeds. Most planetary center driven polishers are fewer than 1,000 RPM. The DS 301 Planetary Polisher variable speed motor operates between 900 to 2700 RPM. The large 12 planetary head rotates at 150 to 450 RPM and the 5 platens that hold the diamond pads, rotate between 750 to 2250 RPM. The three heads operate like a tripod and will always level themselves on the surface. As they randomly spin, they cut the high spots off the concrete, making it flat. If a diamond touches a stone or slab in an improper manner, damage occurs.

Diamond PadsIt is important to match the diamonds to what you are doing. Elna Beck, President of Leitch & Co., points out that the planetary polisher is a wonderful tool, but depends upon understanding which grit and what type of diamond to use for each specific job. She goes on to explain that, diamonds sit on the surface, embedded in a matrix. On a diamond pad, you see the pattern of the diamonds. As the pad wears, new diamonds are exposed on the surface. Diamond Pads are free cutting, constantly cleaning themselves and exposing more diamonds. They are bonded in special, flexible metal or resin matrixes up to 400 grit sizes. Higher diamond grit sizes only use resin matrixes. Courser grits are used in the first grind of a countertop, starting as low as 50 or 100 grit50 grit is good for exposing aggregate when that is desired. Typically, double the grit size for each grind until you reach 3000 or 3500 grit sizesthe highest usually used for concrete countertops.

Matching the Hardness to the MatrixMatch the hardness of the matrix to the hardness of the surface to be ground. The matrix has to wear away as the embedded diamonds wear. This is different for every material being ground. Generally speaking, softer materials wear diamond pads more quickly. Recently, Intertool introduced two different resin matrix materials that are hard and do not wear excessively fast. Using these pads with a hard matrix and fine grit, the final surface is closed down, flat and smooth.

It is important to understand the match of the planetary speed with the diamond abrasive and its matrix. Use the versatility of the speed range to test and to find out what will work with the diamonds you have and the hardness of the surface you are polishing.

More for Concrete Contractors by Leitch & CoThe Trac Star 2000: A concrete saw that runs on a rail like a train, known for its incredible straightness and accuracy. It takes a standard diamond blade and cuts from 1/8 to a 2 1/4 inch depth.

The DS 600:The floor polisher essentially combines two DS 301s and runs them side-by-side connected with an oval over the top. The swatch is 24 inches wide and 12 inches deep. The planetary action is easy to operate on the floor, moves smoothly forward without the typical side-to-side action expected in traditional floor polishing maintenance machinery. Again, the advantage with the size of the motor is to be able to raise the power to high levels for polishing. You can plug it in anywhere. It has a 220 volt line with a converter to 110 and operates with variable speed.

For more information on the products here visit www.inter-tool.com.

Find Concrete Countertop Tools & Suppliers

Jeanne Fields is the owner of Fields Marketing, which provides marketing services for contractors and manufacturers in the decorative concrete industry.