SAW-CUT MASTER:

A Decorative Concrete Contractor Armed with Soff-Cut® Saw and Beveled Blade!Find Concrete Saws & Saw Blades

Before the cracks are there, you make the cut. You bevel edges, round corners, and achieve the perfect-well, close to perfect- "Tooled Joint" look! You create grids, curved designs, edgings, graphics, and wonder where there are additional places to use that saw! Soff-Cut International, Inc., based in Corona, CA, makes this all possible with the introduction of their Ultra Early Entry Concrete Cutting Saws and Diamond Blades that cut control joints-with the option to add chamfer joints, radiuses or V-shaped patterned joints.

Decorative Contractors' Concerns:

Decorative concrete contractors are especially concerned about crack control. Often, the first thing heard from the prospective client is-Will it crack? That's when you launch into an explanation about control cuts, imprinting joints, cutting designs and whether these function as true joints that minimize random cracking. Cuts designed for decoration are typically 1/16th to 1/4 inch deep and do not function as a control joint for a slab on grade.

Soff-Cut Early Entry Systems...Control and Decorative Cuts!

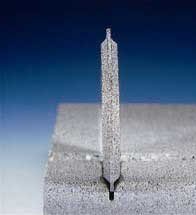

Early entry blade technology cuts control joints and/or makes decorative cuts. Here is how it works: Workers saw control cuts immediately after the last finishing step-just when workers can walk on a slab without leaving a mark. The decorative cutting can start a few hours later depending on temperatures and the amount of cure-or any time later. Almost immediately, there is an opportunity to relieve the stress caused by shrinkage when water leaves the slab. Finishers cut the early entry joint to take care of the cracking issue. Then, in a second step, the decorative blade is inserted into the early entry cut to create the chamfer or radius that will make it decorative.

Saw Cuts with Decorative Flare:

If you make a saw-cut in gray concrete, you create pattern. It can be a grid pattern or a graphic design that stands alone without the addition of color. Saw-cuts also define the location for additional treatments such as color, stain, sandblast or stenciling. Simple grids or complex designs cut into the slab can enhance concrete-taking it from plain gray to multi-colored.

A DISNEY project, Celebrations High School in Orlando, required 300,000 sq. ft. of concrete. The specification included "picture framing" applied to the 10 ft. x 10 ft. and 12 ft. x 12 ft. control sawed areas. However, placements butting up against each other compromised the accuracy of the framing. Soff-Cut salesperson, Dennis Constable offered a solution using the 5/8th inch "v " profile blade. Field samples demonstrated the accuracy of this sawing technique. Following a simple cut an accurate architectural joint was produced after each placement. The engineers liked the difference and changed the spec. The Project Superintendent, John Scibilio, Simcon Construction in Orlando, says "another reason we decided to go with that method of decorative blading was a 20% cost savings." Scibilio continues, "The Celebrations project yielded a second 300,000 sq. ft. job, Triple B High School in Harmony Fl and a third is waiting in the wings!"

Why Try Pro-Edge Beveled or Angle Blades?

A discussion with Kelly Dickenson, owner of Superior Concrete in Riverside CA. was eye opening. Dickinson says, "Using Soff-Cut systems, I am able to triple yield the amount of concrete poured in a day and cut it up without increasing my labor force." As an example Dickenson sites pouring 10,000 sq. ft. of flat work and cutting it into 10 ft. by 10 ft. squares all the same day. The following day he returned to finish the job with decorative sawing. The company also uses Soff-Cut blades to "re-hab" older work. Dickenson reports, "We get calls for warehouse floors where joints crumbled due to heavy wear from fork lift traffic. We use Soff-Cut's angle blades on the vertical cut joint, cleaning up the spalled areas, reshaping the old joint." Homeowners call requesting the same service for their driveways. The company charges an hourly rate for the service. Now, Dickenson who is sold on Soff-Cut, gives back to the company offering to test their products. His discussion reinforced the following points:

-

The Pro-Edge Beveled blades make radius or V-shaped chamfered patterned cuts. You get the beveled look of a tooled joint: beveled edges on a 45-degree angle or rounded corners to 1/4" and 1/2" radius.

-

If a joint needs repair from chipping or spalling, use the angle blade. The blade supplies a clean, crisp edge on either side.

- Larger pours are possible with early entry sawing due to the increased speed of cutting up a slab, -saving labor time, dollars, and increasing profitability.

- The second decorative cut is the opportunity to make additional money with a good profit margin.

What Saws are Best to Use with Pro-Edge Blades?

1. The Soff-Cut Prowler X-50 Handheld saw is designed for finish cuts, scoring, and decorative applications and accommodates the Pro-Edge blades. The blades cut to 1 and 3/16" depth or deliver a shallow cut for a decorative detail. This smaller hand-held saw is excellent for getting close to walls and has a retrieval system to pick up dust for interior and topping applications.

2. The model 310 or X-150 Prowler also accommodates Pro-Edge Blades. These saws are used to chase standard joints for a beveled look after the early-entry dry-cut control joints are cut.

3. The GX -1500 is a self-propelled saw that accepts blades for the deeper control cuts of a thicker slab, still accelerating the process.

Soff-Cut manufactures many Early Entry and conventional saws. In addition to the recommended list, check their website: http://www.soffcut.com (now Husqvarna)

|

|

Or call: 1-800-776-3328

Early Entry Saws and blades have the potential to revolutionize the decorative industry. This technology will change your bottom line for the better! Check it out!

Jeanne Fields is the owner of Fields Marketing, which provides marketing services for contractors and manufacturers in the decorative concrete industry.

Makita Hand Grinder

7.5 AMP motor for high power. Comes with aluminum case.

Makita Hand Grinder

7.5 AMP motor for high power. Comes with aluminum case.

Bosch Combination Hammer

Optimized for one handed use, maximizing productivity.

Bosch Combination Hammer

Optimized for one handed use, maximizing productivity.

Wet Polisher Bundle

Comes with diamond polishing pads.

Wet Polisher Bundle

Comes with diamond polishing pads.