"All of our countertops are custom," said Phil Lampe, Lampe Concrete Studio in San Marcos, CA. "That's one of my rallying cries in the industry. I see some concrete countertop makers coming out with standard colors and standard edge profiles and standard sink shapes. They just try to put some stock pieces together to make countertops and to me that takes away the advantages of concrete. Concrete is so customizable and I think that's one of its big selling points. I like to start with a blank sheet of paper when I go in to see a potential client. Not that I won't reuse colors, but as much as possible I like to have clients think about what they would do if they could do anything and go from there."

Most of Lampe's countertops incorporate an integrally cast-in sink, because he feels that is one of the custom benefits of concrete. "I think that takes advantage of what you can do with concrete that you can't do with other materials."

One recent customized countertop Lampe made featured a rope edge detail. He had gone in to look at the project and found that the bathroom cabinets had a rope detail so he suggested this edge treatment to the customer to tie everything together. "He really liked the idea."

To get this edge on the countertop, Lampe started with some wooden rope molding. "Then I built a form out of the molding and used casting rubber to cast a mold," he said. "I put the rubber mold into my concrete mold and it worked really well. The rubber molding material I use is Smooth-On's Vytaflex. I use it a lot for sink molds and edge details and knockouts or drain boards or things I need to do multiple times."

Not only does Lampe customize the shapes and colors, he makes all his own mixes to take the most advantage of a specific application. "I don't like to use bag mixes because every job is different so I tailor the mix based on what I'm trying to do. In some cases I'll use a very dry hand-packed sand mix and on others I'll use a real fluid mix. I'm not an expert at mix design but I'm getting better."

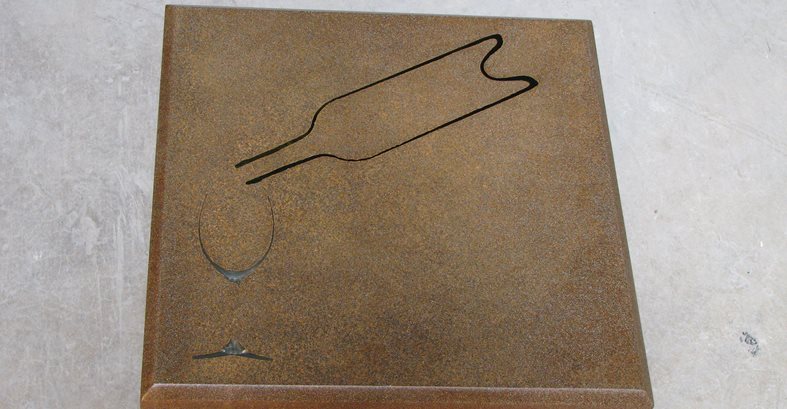

Embedded items are another way to make a countertop unique and Lampe is always on the lookout for objects that would work well cast in to the concrete. "Anytime I go anywhere—any kind of store or shop—I'm always looking for things I can embed in concrete. For the most part clients don't really know what they want, but I have drawers full of things that could be put into the concrete. So when they come in I just start emptying the drawers and showing them things until they see something they like."

Like so many others in the concrete countertop business, Lampe's previous life was completely unrelated. "I spent 20 very successful years as an electrical engineer working for a company that did satellite communications. But I got tired of the corporate world and wanted to try something more creative and hands on. I read Chang's book and that got me interested. I started playing around in the garage and then got more serious and went to a class at the Concrete Countertop Institute and wrote a business plan and thought that this would be a really fun way to make a living. I've been doing it for about 2 years now and I just love it. There's always something new to learn. There are so many things you can do or try or experiment with--it's really unlimited. It seems like I could spend the next 2 or 3 years just doing R&D."

Lampe Concrete Studio

Phil Lampe

935 Bailey Ct Ste 104

San Marcos, CA 92069

(760) 331-8237

Submit your own project photos

See more concrete bathroom countertops