- Industrial floors home

- Design & construction of commercial/industrial floors

- Floor flatness and joints

- Concrete Floor Applications

- Staining Concrete Floors

- Painted Concrete Floors

- Stenciling Concrete Floors

- Polishing Concrete Floors

- Self-Leveling Concrete Overlays

- Related Information

- Commercial Concrete: Information about concrete used in retail stores, restaurants, offices, and more

- Retail Floors

- Subgrades and subbases for concrete slabs

- Jointless slabs: How to reduce or eliminate the number of joints

Industrial Concrete Floor Finishes

Learn what makes industrial floors different from typical concrete floors and the special requirements for industrial floor design and constructionConcrete floors, whether used in a residential basement, a big-box store or a manufacturing plant, are basically the same. Learn about these popular applications:

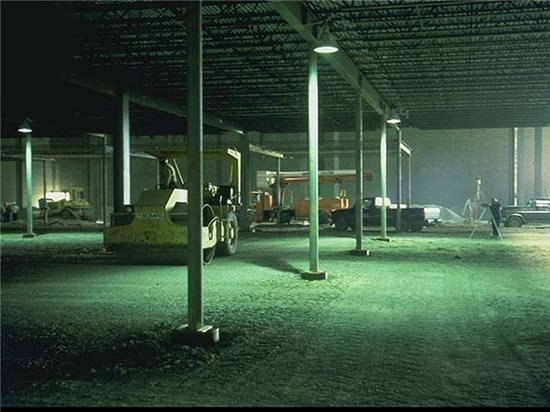

In commercial or industrial settings, though, the slabs usually have special requirements based on the loads or flatness or levelness required. To get a slab that meets these requirements, the contractor will use special techniques in placing and finishing the concrete. Commercial or industrial floors can also have special requirements for surface hardness, finish, and even color. Wal-Mart, for example, has a specification for their exposed concrete floors that incorporates color, surface densifiers, and a hard troweled finish. That company has high expectations for everything and their concrete floors are no exception.

Commercial / Industrial (C/I) floors can be built on grade or can be suspended. Suspended floors are often built on metal decking, which is corrugated sheet metal supported by structural steel. Achieving high flatness and levelness values on these floors can be difficult since the decks and frames deflect under the weight of the concrete.

Materials, Site Preparation and Placement Environment for Commercial Floors

Materials Used for Commercial FloorsCommercial or industrial floors tend to be large placements that are susceptible to curling and cracking. A lot of that can be controlled by using the right materials and in the mix designs. The key is to use the largest possible aggregate (since aggregate can't shrink), to get a well-graded aggregate (meaning there is aggregate of every size from larg- to small), and to use the lowest water content possible. Learn more about mix design.

Placeability and finishability are also critical to getting a good slab and there is a certain amount of trade-off necessary to accomplish these equally important goals of a durable floor that's easy to place. For an extensive explanation of good mix proportioning for commercial or industrial floors, check out Chapter 6 of ACI 302.1R-04. Here are a few important points:

-

The maximum size of coarse aggregate should not exceed 3/4 the minimum clear spacing of the reinforcing bars in structural floors, or 1/3 the thickness of non-reinforced slabs. Aggregates as large as 1.5 inches, though, can often be used.

-

Fly ash or slag cement commonly appears in commercial or industrial floors. These materials (along with silica fume) are called supplementary cementitious materials or pozzolans and have various purposes as a cement replacement. I have always refused to call pozzolans admixtures, although many people do. According to the strict definition from ACI, it would seem that pozzolans are admixtures because they are "a material other than water, aggregates, hydraulic cement, and fiber reinforcement, used as an ingredient of a cementitious mixture to modify its freshly mixed, setting, or hardened properties and that is added to the batch before or during its mixing." But to me, a pozzolan is really a cementitious material and therefore not quite the same as an admixture. Some call these materials mineral admixtures. I simply call them SCMs; you can decide what you want to call them, if you want to call them at all.

-

A material sometimes used with commercial or industrial floors is expansive cement (also called shrinkage-compensating cement). Shrinkage-compensating concrete expands slightly while setting then shrinks back to its original size. When done properly this can eliminate cracking and increase the spacing of control joints, but it requires an experienced concrete contractor and ready-mix producer to get everything to work properly.

-

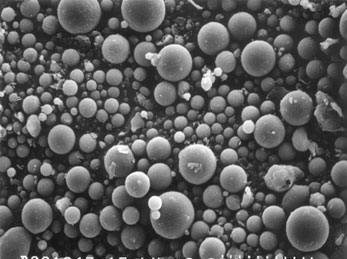

Hard, wear-resistant aggregates such as quartz, emery, and traprock, as well as malleable metallic hardeners, are frequently used as surface treatments in commercial or industrial floors. They are applied to the top surface as dry shakes and finished into the surface of the floor to improve the abrasion resistance of the surface.

-

Reinforcement comes in various types, these include welded wire fabric (mesh), steel reinforcing bars (rebar), synthetic fiber reinforcement (0.75 to 1.5 pounds/cubic yard), and steel fibers (34 to 68 pounds/cubic yard). Synthetic fibers, commonly polypropylene, are primarily useful for preventing plastic shrinkage cracking. Some fibers, such as steel fibers, can improve concrete flexural strength.

DAY1 Finishing Aid

Improve finish, reduce defects, enhance performance

DAY1 Finishing Aid

Improve finish, reduce defects, enhance performance

Industrial Floor Wax

Achieve superior long term wear

Industrial Floor Wax

Achieve superior long term wear

Industrial Repair Products

Fix floors with cracks, spalls and gouges

Industrial Repair Products

Fix floors with cracks, spalls and gouges

Polishing Diamonds

Options for hard, medium, and soft concrete.

Polishing Diamonds

Options for hard, medium, and soft concrete.

Encore Finishing Aid

Improve workability and surface quality

Encore Finishing Aid

Improve workability and surface quality

Propane Grinding Machines

Go cordless with the LAVINA elite gtx series

Propane Grinding Machines

Go cordless with the LAVINA elite gtx series

Site Preparation & Placement Environment

All concrete slabs on ground require good subbgrade or base beneath to support the concrete. But note that the critical thing is uniform support. Soft spots are the death of any slab. Here are a few things to keep in mind about the subgrade (the ground beneath the slab) and the subbase (an optional compacted gravel layer between the concrete and the subgrade):

-

Grading of the subgrade—or rough grading--should meet a tolerance of +0 inch/–1½ inches. Get a rod and level survey done to make sure the subgrade complies with this tolerance before the excavation equipment is taken off site. Take measurements at 20-foot intervals in two perpendicular directions.

-

Base tolerances—or fine grading--should meet a tolerance of +0 inch/–1 inch for floor Classes 1 to 3 and +0 inch/–3/4 inch for floor Classes 4 to 9. This elevation is measured from the specified bottom of the slab.

-

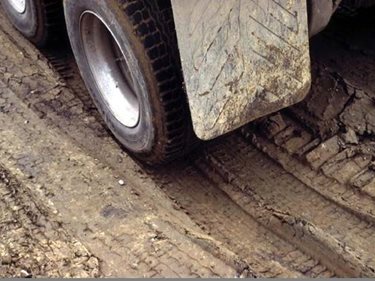

The base material should be compactable, easy to trim, granular fill that will remain stable and support construction traffic. To test this, perform proof rolling on a grid pattern for the entire slab area.

-

Proof-rolling is the most effective ways to determine if the soil support system will provide uniform and adequate bearing support during construction and for the life of the slab. Proof rolling involves driving a fully loaded dump truck or ready mix truck across the subgrade or subbase. If any of the wheels sink in deeper than ½ inch, that area will need to be recompacted.

-

Vapor barriers are essential beneath most interior concrete floors, especially if there is any intention of installing moisture-sensitive floor coverings (tile, wood, vinyl, etc.). In general, the vapor barrier should be directly beneath the concrete. Learn more about vapor barriers.

-

Learn more about subgrades and subbases.

-

Whenever possible, install floor slabs in a controlled environment. Ideally the roof should be on and the walls in place—protecting the soil support system and the concrete slab from wind, rain, sun, and extreme temperatures will greatly improve the slab. Learn more about cold weather techniques and hot weather techniques.