- Staining Concrete

- Stamped Concrete

- Concrete Overlays

- Concrete Resurfacing

- Concrete Polishing

- Concrete Dyes

- Colored Concrete

- Indoor Concrete

- Concrete Floors

- Concrete Countertops

- Garage Floor Coatings

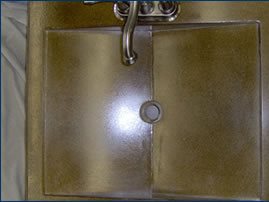

- Furniture, Sinks, Fire Bowls

- Basement Floors

- Outdoor Concrete

- Concrete Patios

- Concrete Driveways

- Concrete Pool Decks

- Outdoor Kitchens & Counters

- Outdoor Fireplace

- Concrete Walkways

- Concrete Pavers

- Concrete Walls

- Repair & Maintenance

- Foundation Repair

- Concrete Crack Repair

- Concrete Sealers

- Building with Concrete

- Concrete Homes

- Concrete Basements

- Decorative Concrete

- Fire Resistant

Unique Work is Key for Tennessee's World Concrete

In Gray, Tenn., Matthew Bray is busy running his decorative concrete business, World Concrete, focusing on projects that are unique and one of a kind. The business he started just nine years ago at first focused on flatwork—driveways, sidewalks and the like—and in more recent years has shifted to decorative concrete via countertops and sinks.

World Concrete, which serves the Tri-City area, as well as parts of North Carolina, southwest Virginia and into Knoxville, Tenn., has a portfolio comprised of about 70 percent exterior (flatwork) and 30 percent interior (decorative work), with a 50/50 split between residential and commercial projects.

The company offers acid etch staining, colored concrete, countertops and elements, driveways, engraving, landscape borders, patios and walkways, pool decks, concrete resurfacing, finished basements, interior concrete flooring, stamped concrete, and water features.

They do their own work—from grading, to forming, to pouring and finishing—on residential and commercial driveways, basements, garages, sidewalks and decorative concrete (including stamping, staining, countertops and sinks).

Originally, World Concrete was a home-based, small operation in Kingsport, Tenn. However, Bray says that consistent growth through the years has allowed the company to expand, accept larger jobs, build a reputation, obtain consistent customers with strong references, and increase the types of concrete products they provide.

Their foray into concrete tables provides a stunning example of the customization, options and quality the company focuses on. For Bracken Paving, Bray and his crew provided a 7-foot by 5-foot concrete conference table weighing 750 lbs.

First, using a two-foot sonotube for the base, Bray siliconed it to plexiglass and put an 8-inch pipe in the middle, using plexiglass to divide it though the center. He then integrally colored the base black before sandblasting the outside to look like asphalt. Bray used a split-face granite edge form liner for the table, and a Modello custom stencil and Smith paint dye applied with HVLP. The whole thing was topped with a two-part epoxy sealer.

Another project, a coffee table for a private residence, also yielded beautiful results. Bray says he poured the table "Cheng style" using melamine and Scoffield's padre brown and terra cotta integral colors and stains to make the table look like worn leather, before polishing parts of it to look like burnt wood. The legs were custom made by a woodshop, and there's not one single exposed screw in the whole piece.

Because World Concrete focuses on custom works, they offer custom countertops of nearly unlimited design possibilities, including a multitude of color, edging, shape, size and inlay options.

Their sink line includes both vessel and farm sinks, as well as any form, color and seal to fit any need. Stamping options such as slate, stone and brick, as well as custom coloring and acid stain, can also create unlimited color variations and mixtures.

World Concrete has recently been exploring the many options in aggregates, including grading rock so, for example, when someone says they want 70 percent Nolichuckey stone and 30 percent pink granite, they get what they want.

"People are excited about seeing the stone right now," Bray adds of the increase in demand for aggregate work, noting that he's also been getting a lot of requests for decorative saw cuts and acid stained flatwork.

"But we're trying to get away from acid stain and move to dyes," he explains. "We want to be able to replicate a test sample exactly, which dyes allow us to do more so than acid stain...there's so much more control with water-based stain. I think acid stain's days are numbered."

World Concrete is also using aluminum shavings and copper inlays in countertops, which Bray says provides a one-of-a-kind look that attracts customers and keeps the work interesting for him.

"What we see as the future for us is totally custom, one-of-a-kind work," he concludes. It seems World Concrete is already there.

World Concrete

Quentin Horton and

Beth Koontz

166 Cedar Creek Road

Gray, TN 37615

(423) 979-7172 Office

(866) 408-7172 Toll Free

(423) 340-0909 Quentin's Cell

(423) 467-0035 Fax

Send Mail Now - Click Here

http://www.world-concrete.com