- Concrete joints home

- Isolation joints

- Construction joints

- Contraction joints

- Locating & Filling Joints in Concrete Slabs

- Be active in deciding where to place control joints

- Joints in commercial floors

- Sealing joints- Tips for sealing and filling joints

- Related Information:

- How to build high-quality slabs on grade

- Groover tools for forming joints

Sealing Joints

Things to consider when sealing or filling concrete jointsSealers and fillers for concrete joints are not the same thing and have very different purposes. While it's not always necessary to seal or fill a joint, here are a few things to think about:

- A sealer is soft and able to accommodate the concrete slab's expansion and contraction. The sealer's purpose is to prevent water, ice, and dirt from getting into the joint (and into the subgrade) and to prevent intrusion from below the slab—including of radon. Sealers can also improve the appearance of floors and slabs.

- A filler is a rigid material that supports the edge of the joint when heavy traffic crosses. This type of material is only effective with saw-cut joints; rounded tooled edges can't support the filler.

- Both sealers and fillers should only be installed after the slab has had a chance to shrink as much as possible. Fillers are only effective if installed after the concrete has gone through most of its shrinkage, although that can take a year or more. Fillers and sealers should be checked at the end of the first year of service and repaired or replaced as needed.

- Effective sealant materials must bond to the concrete, be impermeable, and be able to handle the expansion and contraction.

- Before installing a sealant, the joint must be dry and free of dust and debris. Vacuum it thoroughly before sealing. Carefully follow the sealant manufacturer's installation instructions.

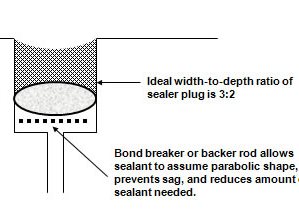

- For sealers, use a bond breaker or backer rod in the bottom of the joint. This prevents the sealer from sagging into the joint and from adhering to the bottom of the joint, which allows the sealant to stretch on both the top and the bottom.

- A backer rod in the joint also keeps the sealer plug thinner, reducing the amount of sealant needed.

- Although the best theoretical shape of the sealant plug would be 1:2 (depth-to-width ratio), ACI 504R-90, Guide to Sealing Joints in Concrete Structures, recommends that a better ratio is 3:2, since this allows the sealant to adhere better to the sides of the joint. Newer sealers, however, may work at lower ratios. Read more about Sealing Joints in Concrete.