- Concrete Molds Home

- Countertop Molds

- Sink Molds

- Stamp & Texturing Tools

- Edge Molds

- Tips for Making and Using Concrete Molds

- Making molds from rubber

- Related Information:

- Concrete countertop forming videos

Concrete Molds

A guide to buying or making your own formwork for concrete countertops, sinks, furniture, patios and walkwaysNearly all concrete placed anywhere is molded in one way or another. A mold is really the same thing as concrete formwork—or shuttering if you're British. But it's usually only called a mold when it is smaller, more detailed—such as for a countertop or a sink or concrete furniture. Although some people refer to stamped concrete surfaces as being molded when referring to the pattern or texture, such as on patios and walkways.

A popular feature of concrete countertops is an integral molded sink. "I do lots of integrally cast-in sinks," said Phil Lampe, Lampe Concrete Studio, San Marcos, California. "I think that takes advantage of what you can do with concrete that you can't do with other materials."

Countertop makers mold these sinks either with their own custom-made molds or with purchased molds. What the molds have in common is that they must be smooth and waterproof and able to hold the concrete in place until it sets. Materials that meet those requirements include fiberglass, Plexiglas, rubber, and polystyrene.

Concrete molds can also be used to create the following:

- Fire bowls

- Fireplace mantels

- Coffee tables

- Benches

- Planters

- Statues

- Stepping stones

In this article, you will learn a little about countertop molds and a little more about sink mold and countertop mold inserts. For a detailed explanation of how to make a countertop mold, get a copy of Fu-Tung Cheng's book, Concrete Countertop Book.

Molds are used to make sinks and concrete furniture. Buddy Rhodes Concrete Products

Unusual shapes often require custom made molds. Lampe Concrete Studios in San Marcos, CA

Molds are used to make sinks and concrete furniture. Buddy Rhodes Concrete Products

Unusual shapes often require custom made molds. Lampe Concrete Studios in San Marcos, CA

Tips on Making Molds from Rubber

Liquid rubber is a great way to make durable perfectly smooth molds.

Tips on Making Molds from Rubber

Liquid rubber is a great way to make durable perfectly smooth molds.

How to Use Manufactured Sink Molds

Prefab sink molds are a great way to create custom concrete sinks for bathrooms and kitchens

How to Use Manufactured Sink Molds

Prefab sink molds are a great way to create custom concrete sinks for bathrooms and kitchens

Countertop Molds

Discover what materials are best for forming concrete countertops

Countertop Molds

Discover what materials are best for forming concrete countertops

Custom Concrete Molds

Of course, you don't have to use a standard mold. You can get custom molds from most of the companies that have manufactured molds or you can make your own using liquid rubber.

Single-use molds can be made from expanded polystyrene (EPS) with a slick plastic coating that results in a very smooth finished surface. You can also work with a company that has specialized equipment for making custom molds. These controlled foam carving systems allow you to create anything you can imagine. Remember that you always have to think in terms of a negative to get your positive countertop to turn out the way you envision it.

Concrete Mold Reviews

An inside look at the latest molding products:

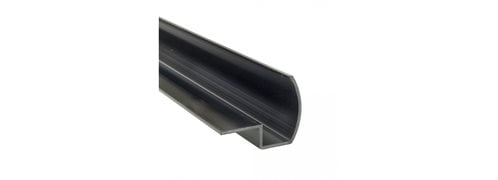

Slot Drain Ramp Sink Mold

72" with internal reinforcement

Slot Drain Ramp Sink Mold

72" with internal reinforcement

Rectangle Sink Mold

Internally reinforced. Ships in 2 to 3 business days.

Rectangle Sink Mold

Internally reinforced. Ships in 2 to 3 business days.

Mold Making Kit

Create custom rubber molds for concrete casting

Mold Making Kit

Create custom rubber molds for concrete casting