- Concrete Stencils Home

- Paper or plastic The pros and cons of each

- Stock or custom concrete stencils: Which type fits your design needs?

- Adhesive or nonadhesive stencils: When to use each type

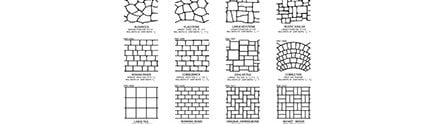

- Concrete stencil patterns: View some of the options

- How-To Tips for Using Stencils

- Step-by-step process of applying stencils

- Using microtopping and stencils to rejuvenate ugly concrete

- Related Information:

- Stenciling Concrete Floors

- "Floor Me" video series: Stencil design ideas and techniques

- Concrete logos and graphics: Creating images with concrete stencils

- Bob Harris' five favorite methods for creating graphics on floors

Paper Concrete Stencils vs. Plastic

Most stencils are made of heavy-duty paper or plastic (such as vinyl or Mylar). Paper stencils typically come in rolls, like wrapping paper, that cover approximately 1,000 square feet or, in the case of borders, 100 to 300 lineal feet. You can also buy smaller half rolls of 500 square feet as well as circular designs or rosettes sold as individual sheets. The best-quality paper stencils are made of tear-resistant paper or cardboard covered with a water-resistant waxy coating to prevent deterioration and to ease release. Pattern options are generally limited to repeating designs such as brick, slate, tile or cobblestone.

Stencils come in two materials: paper or plastic.

Stencils come in two materials: paper or plastic.

Stenciled cobblestone driveway. ArtistiCrete in Noblesville, IN

Stenciled cobblestone driveway. ArtistiCrete in Noblesville, IN

Paper Stencils for Exterior Concrete

Time: 01:05

Find out when and why paper stencils are used in specific applications.

Plastic stencils come in sheets, rather than rolls, and are well-suited for projects requiring custom designs. They tend to be more resilient than paper stencils and can be cut into more intricate patterns, permitting unlimited designs (see "Stock or Custom?"). The size of the stencil will vary depending on the pattern, but the typical sheet size is 4x8 feet.

Paper stencils are much cheaper initially than plastic stencils. A 1,000-square-foot roll ranges in price from $200 to $350 vs. $80 and up for a single 4x8-foot plastic stencil. But you can't reuse paper stencils and must dispose of them after each project. Some plastic stencils, on the other hand, are reusable and can be cleaned after each job and saved for other projects. These stencils can be a good investment if you do a lot of decorative work using the same patterns. Specialty Concrete Products, for example, says that its reusable plastic stencils will provide years of use. However, you do need to keep the stencils flat during storage to prevent curling or crimping.

Reusable Urethane Stencils

New Technology - leaves crisp clean designs

Reusable Urethane Stencils

New Technology - leaves crisp clean designs

Decorative Stencils

Adhesive or non-adhesive, slate, brick, etc.

Decorative Stencils

Adhesive or non-adhesive, slate, brick, etc.

Paper Stencils

Thick, tear resistant & a wide variety of patterns

Paper Stencils

Thick, tear resistant & a wide variety of patterns

For new concrete, paper stencils are generally the best choice, especially if you are covering a large area. That's because when stenciling newly poured concrete, you need enough stencil material to cover the entire surface, which could become cost-prohibitive when buying individual sheets of plastic. Plastic stencils are also less flexible and can be difficult to float into new concrete.

On existing or hardened concrete, both paper and plastic stencils can be used, However, plastic stencils tend to lay flatter and are less prone to distortion. They work especially well on projects involving sandblasting or the application of a thin overlay to create a pattern relief (a technique called "embossing"). Some manufacturers offer plastic stencils in different thicknesses to achieve varying degrees of relief. Not all overlay materials work well with stencils, however, depending on the overlay thickness and how it's applied. Make sure you use an overlay system suitable for stenciling. (For more information, read "Comparing Types of Overlays Systems.")