- Concrete Stencils Home

- Paper or plastic The pros and cons of each

- Stock or custom concrete stencils: Which type fits your design needs?

- Adhesive or nonadhesive stencils: When to use each type

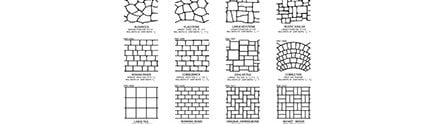

- Concrete stencil patterns: View some of the options

- How-To Tips for Using Stencils

- Step-by-step process of applying stencils

- Using microtopping and stencils to rejuvenate ugly concrete

- Related Information:

- Stenciling Concrete Floors

- "Floor Me" video series: Stencil design ideas and techniques

- Concrete logos and graphics: Creating images with concrete stencils

- Bob Harris' five favorite methods for creating graphics on floors

Reusable Stencils Bring a New Dimension to Decorative Concrete

Necessity is the mother of invention, and for decorative concrete contractor Grant Farrell, his need for a tool that would allow him to make decorative impressions in all kinds of finishes—not just stamped concrete—led to the brainchild of what would become a new line of urethane stencils called Concrete Dimensions, now available from the Brickform division of Solomon Colors.

“After years of placing exposed aggregate and stamped concrete, Grant felt a need for something new,” says Solomon Colors marketing coordinator Aaron Szerletich. “The tools needed to be rigid enough to create a detailed impression in wet concrete. They also had to be flexible enough to be rolled up for storage and durable enough to withstand repeated use by contractors. Most importantly, however, the stencils needed ‘memory’ so they could be laid flat and retain their shape. After seven years of trials using different types of rubbers, silicones, and plastics, urethane was determined to be the best material to meet these requirements.”

After some time using the new stencils within his own company, Farrell partnered with Solomon Colors to bring them to a wider market. The stencils have now been incorporated into the Brickform product line and can be used alone or in combination with Brickform’s concrete texture skins and mats.

How they work

Concrete Dimensions are designed as an early-entry tool to be floated into freshly placed concrete. Once the stencils are embedded, you can continue with nearly any finish, from smooth troweling to exposed aggregate. After the concrete has hardened, simply pull up the stencils to leave behind a clean, crisp impression.

Key advantages

Reusability is the single greatest advantage Concrete Dimensions has over other stencils, says Szerletich. “Since they are made with a durable urethane instead of paper, Concrete Dimensions can be used time and time again.”

Versatility is another attribute. The stencils are compatible with a wide variety of finishes including sand finishes, all levels of exposed aggregate, broom finishes, and rock salt finishes. They also are available in a variety of designs, including compass roses, medallions, decorative borders and custom line art.

For more information about Concrete Dimensions, visit the Brickform website.

Watch a video of Szerletich explaining how the new stencils work at World of Concrete.

Reusable Urethane Stencils

New Technology - leaves crisp clean designs

Reusable Urethane Stencils

New Technology - leaves crisp clean designs

Decorative Stencils

Adhesive or non-adhesive, slate, brick, etc.

Decorative Stencils

Adhesive or non-adhesive, slate, brick, etc.

Paper Stencils

Thick, tear resistant & a wide variety of patterns

Paper Stencils

Thick, tear resistant & a wide variety of patterns