- Concrete Furniture Home

- Concrete Furniture Photos

- Concrete Furniture Types

- Concrete Coffee Tables

- Outdoor Concrete Furniture

- Concrete Office Furniture

- Concrete Storage Furniture

- Concrete Ping Pong Tables

- Design Ideas

- Concrete Furniture Design Ideas: Behind-the-scenes info and photos

- Free Concrete Furniture Catalog

- Related Information

- Learn How to Make Bent Concrete Furniture

- Concrete Contractors: Find GFRC Mixes for Precast Concrete

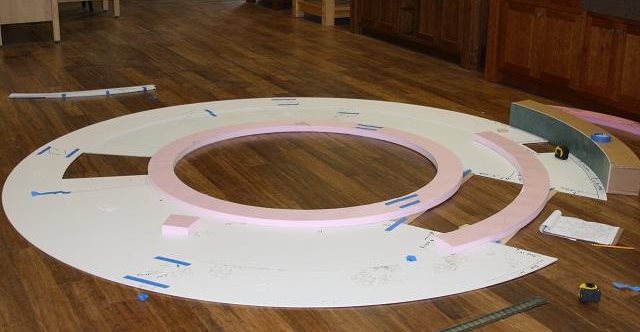

Circular Concrete Reception Desk Welcomes Hotel Patrons in Style

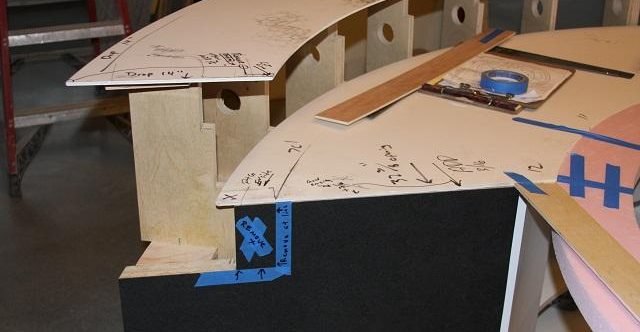

This custom 10-foot-diameter desk, created using computer-aided design software and environmentally friendly concrete, reflects hotel's contemporary flairThe challengeTo build a state-of-the-art concrete reception desk for the Aloft Hotel in downtown Milwaukee, a modern five-story, 160-room facility featuring loft-inspired design. In addition to the curvilinear shape, the desk had to be built to discretely accommodate storage cabinetry and computer systems and minimize their view to the public.

Materials used

- Concrete mix: CustomCreteWerks N-viroCrete™, a lightweight environmentally friendly concrete, made from recycled materials

- Sealer: CustomCreteWerks N-hansed™ StainProof sealer

- Integral color: Rocky Mountain gray from the CustomCreteWerks Design Series line

Secrets to successTo achieve a precise radius, CustomCreteWerks used computer-aided design software (from SolidWorks) to draw the desk and a CNC router to cut all templates and forms. The top was made in four pieces, the lower counter in three pieces, and the backsplash in five pieces for easier assembly.

Green features

- The N-hansed StainProof surface requires no resealing and only routine cleaning.

- N-viroCrete concrete incorporates recycled pozzolans.

- The desk was locally manufactured at the CustomCreteWerks shop in Racine, Wis. Materials and supplies were also purchased locally and in bulk when possible.

Lessons learned"The biggest challenge was working with the cabinetmaker," says Farrey. "Due to inconsistencies, we had to re-template the structure after it was installed and make more changes before casting. Next time, we will supply a CNC template to the cabinetmaker and one for the jobsite. This will allow us to manufacture everything earlier and accommodate tight deadlines."

ManufacturerDan Farrey, President

CustomCreteWerks

Racine, WI 53404

Submit Your Own Project Photos

Urethane Furniture Molds

Log tables, benches and more

Urethane Furniture Molds

Log tables, benches and more

Imperial Mix

Lightweight, strong, minimal shrinkage

Imperial Mix

Lightweight, strong, minimal shrinkage

Table Top Molds

Live edge, compass, flags, checkboard, etc.

Table Top Molds

Live edge, compass, flags, checkboard, etc.