- Pouring Concrete in Hot Weather

- Concrete Admixtures for Hot Weather

- Curing Concrete in Hot Weather

- Related Resources

- Pouring Concrete in Cold Weather

- Can You Pour Concrete in the Rain?

- Concrete Mix Design

- Types of Admixtures for Concrete

Section Sponsor

Packaged Admixtures

Seasonal Pouring Tips

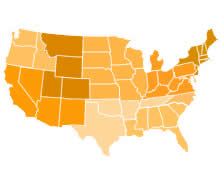

Get guidelines for placing concrete by region and season throughout the U.S.

SELECT A REGION

Hot Weather Concrete Curing

How to cure concrete in hot weather using curing compounds or blankets

On plain gray concrete, a white pigmented curing compound can help reflect some heat from the sun.

Federal Highway Administration

Curing is critical any time, but especially in hot, dry weather and it needs to start as soon as your finishing operations are completed. With plain gray concrete, use a white pigmented curing compound that will help reflect sunshine. If you are using a curing blanket, use the white ones, either the single-use variety or the multiple use (Read more about curing concrete).

If you use a curing compound, make sure it is doing its job. Kozeliski advises running this test: "Put a 3-foot-square piece of plastic on the slab and put sand around the edges. Come back a little while later and if there's moisture under the plastic, the curing compound isn't doing the job. Often contractors get cracks and blame the concrete when actually it's that the curing compound didn't really work."

White curing blankets will help keep the concrete cooler by reflecting the sun. PNA Construction Technologies.

HOW TO DEAL WITH HOT WEATHER ON THE JOB SITE

If you start with concrete below 80°, then your objective is to keep it cool and to not let it dry out. In very hot weather, place the concrete early in the morning or later in the evening. Be prepared! Make sure your crew and all equipment are ready to go when the concrete arrives so you can get the concrete out of the truck-it can heat up a lot just sitting in the mixer waiting to be placed. Friction within the concrete during mixing can generate enough heat to raise the concrete temperature 5° in 30 minutes.

Learn more about Pouring Concrete in Hot Weather.

If slump loss becomes a problem, rather than adding excessive water, try using a superplasticizer (high-range water reducer). These admixtures can increase slump without affecting the concrete's final strength or appearance.

Learn more about Concrete Admixtures for Hot Weather.

Mini Delayed Set

Good for step-delay concrete pouring

Mini Delayed Set

Good for step-delay concrete pouring

Rescue-Pak

Contains six of our most effective admixtures

Rescue-Pak

Contains six of our most effective admixtures

Standard Delayed Set

Dry Powdered Admixture

Standard Delayed Set

Dry Powdered Admixture

Keep the sun off the concrete surface if at all possible-for interior slabs, try to place after the building has been closed in; outside, use sun shades. Also keep all of your tools and equipment out of the sun, especially things like pump hoses that will come in direct contact with the concrete.

For exterior concrete, where you are placing on a subgrade, wet down everything, subgrade and forms, with cool water prior to placing the concrete so moisture isn't absorbed from the concrete, which can lead to cracking. "Wet the subgrade so that the moisture goes all the way through the 4 inches," says Kozeliski. "Too often the contractor only wets the top 1/16 inch and it sucks the water all out."

As soon as the concrete is down and bull floated, use a monomolecular film, or evaporation retarder. These materials evaporate after a couple of hours and have no negative impact on the concrete but will prevent the evaporation of surface water. Monomolecular film will prevent plastic shrinkage cracking and surface crusting.