- Concrete Tools Home

- Screeds

- Tampers

- Concrete Floats

- Concrete Edgers

- Groovers

- Trowels

- Fresnos

- Power Tools for Concrete

- Choosing the Best Tool for the Job

- Must-Have Tools for Exterior Concrete: The five tools outdoor concrete contractors can’t live without

- Five Must-Have Tools for Decorative Flooring Contractors Create eautiful decorative concrete floors with these five tools

- Five Must-Have Tools for Concrete Countertop Contractors

- Related Information:

- Pouring and Finishing Tool Videos: See demonstrations of floating, troweling, edging, and more

- Concrete Finishing Tips: Creating a high-quality slab

- Product Newsletter: Sign up today to receive monthly updates

Concrete Edger Tools

Which edgers to use and when and how to edge concreteConcrete edgers produce a neat rounded edge along the slab perimeter which helps the slab resist chipping and spalling damage after the forms are removed. An edger looks like a small trowel with one curved side.

WHEN & HOW TO EDGE CONCRETE

Perform edging after the bleedwater disappears from the concrete surface, but before the forms are removed. The concrete should be firm, but still workable. Edging can be done along with jointing.

On most floors, edging will not be required, but on patios, curbs, sidewalks, and driveways, it produces a tighter, cleaner looking edge that is more resistant to chipping.

You can edge by hand, which requires kneeling next to the slab and performing the edging operation. Or you can use a walking edger that attaches to a handle and allows the finisher to walk alongside the slab to edge the concrete.

PICK THE RIGHT EDGER FOR YOU

Different edgers produce different edge radiuses. There are special edgers for steps and curb and gutter work. Hand edgers range in size from 1 1/2 to 6 inches wide and 6 to 10 inches long. A lip on one side of the tool, which forms the edge, comes in various radiuses (from 1/8 inch to 2 inches) and depths (from 3/8 inch to 1 1/2 inches).

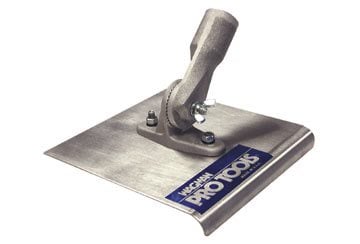

Walking Edger

Bon Tool, 4 depths

Walking Edger

Bon Tool, 4 depths

Kraft Concrete Float 24" x 3.25"

Lightweight magnesium float for small areas.

Kraft Concrete Float 24" x 3.25"

Lightweight magnesium float for small areas.

Laminated Wood Bull Float

Draws excess water to surface. Bracket assembly kit included.

Laminated Wood Bull Float

Draws excess water to surface. Bracket assembly kit included.

Buying tips:

-

Bronze edgers are usually heavier, thicker, and more expensive than steel edgers although some manufacturers offer heavy-gauge stainless steel edgers that are said to be stronger than traditional bronze. These tools tend to last longer and produce a smoother, denser edge, often making them worth the extra investment.

-

Edgers are available with front and back ends that are either flat or curved upward. Curved ends help prevent the tool from gauging the concrete.

-

Edgers with comfort-grip handles cost slightly more than models with wood handles, but the softer grip helps reduce hand fatigue.

-

To minimize bending and kneeling, you can buy walking edgers that attach to wood handles. Two types of handle brackets are common. One allows flipping of the handle from one side to the other for easy two-way use, and the other swivels to allowing locking of the handle at any point in a 360-degree radius.

Average costs:Prices for edgers can vary significantly, depending on the quality of the blade. You'll spend a mere $5 or $6 for a 6x3-inch blue-steel edger and as much as $25 for a bronze or heavy-gauge stainless steel tool.