- Concrete Tools Home

- Screeds

- Tampers

- Concrete Floats

- Concrete Edgers

- Groovers

- Trowels

- Fresnos

- Power Tools for Concrete

- Choosing the Best Tool for the Job

- Must-Have Tools for Exterior Concrete: The five tools outdoor concrete contractors can’t live without

- Five Must-Have Tools for Decorative Flooring Contractors Create eautiful decorative concrete floors with these five tools

- Five Must-Have Tools for Concrete Countertop Contractors

- Related Information:

- Pouring and Finishing Tool Videos: See demonstrations of floating, troweling, edging, and more

- Concrete Finishing Tips: Creating a high-quality slab

- Product Newsletter: Sign up today to receive monthly updates

Concrete Trowels - Hand Trowels & Power Trowels

How to use a concrete finishing trowel to produce a smooth, dense surfaceTroweling produces a hard, smooth, dense surface and should be done immediately after floating. Troweling can be done by machine or by hand. If done by hand, the finisher will float and trowel and area before moving his knee-boards.

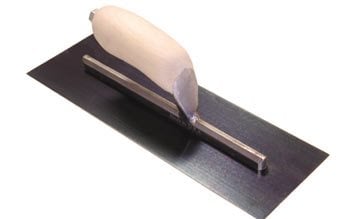

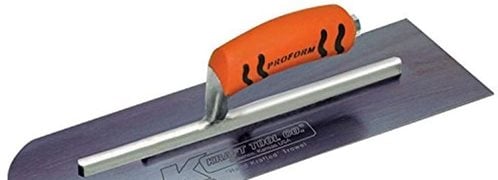

STEEL TROWELS

Purpose: Used after floating to produce a smooth, hard, dense slab surface.

What's available: Steel trowels look similar to hand floats, except the blades are thinner and the handles are open rather than closed. The key difference among tools is the type of steel used for the blade. The most common types are blue, stainless, and high-carbon steel. Blue steel is thin and lightweight, so it flexes slightly under hand pressure. Stainless steel blades will not rust or stain concrete surfaces. Trowel dimensions from range from 3 to 5 inches wide by 10 to 24 inches long.

A fresno is a steel trowel attached to a bull-float handle. Putting a long handle on the trowel allows finishers to trowel the concrete without walking out onto the slab. Fresno trowels do not, however, produce the same density or wear resistance that is produced by multiple hand trowelings where the finisher can apply greater pressure to densify the concrete.

Buying tips:

-

Be sure to purchase an assortment of trowel sizes. Generally, a 14 x 4-inch or 16 x 4-inch trowel can tackle most decorative finishing jobs. But on large projects or when you need to cover more area faster, then a larger fresno (see description below) will be the most efficient. For small patching jobs or when working in tight areas (such as corners, steps, and around floor pipes and drains), you'll need a smaller tool, such as an 8x3-inch midget trowel.

-

Trowels are less likely to gouge the surface after they're broken in because the blades become slightly curved and the edges beveled. If you want to fast forward past the break-in process, you can purchase trowels that have been "broken in" (the edges are pre-ground) at the manufacturing plant.

-

Most trowels come with a choice of camel-back or straight wood handles or more resilient comfort-grip handles. Camel-back handles have a slight upward curve that provides more knuckle clearance. Choose the handle type you find most comfortable to grip and gives you the best control. Also look for handles with sturdy aluminum shanks that are securely riveted to the blade.

Average costs: For a 14x4-inch trowel, the cost ranges from about $24 to $40, depending on the type of steel used. Stainless steel trowels usually cost a few dollars more than trowels made of blue or high-carbon steel.

Multiple Trowelings:

More than one troweling can be done: as the concrete sets each successive troweling should be made with a smaller trowel tipped at a greater angle than the last troweling. This increases pressure on the surface producing maximum floor smoothness and hardness. However, hard troweled surfaces are not suggested for outdoor surfaces since they become slippery when wet.

Blue Steel Hand Trowel

Kraft Tool via Amazon

Blue Steel Hand Trowel

Kraft Tool via Amazon

Kraft Concrete Float 24" x 3.25"

Lightweight magnesium float for small areas.

Kraft Concrete Float 24" x 3.25"

Lightweight magnesium float for small areas.

Laminated Wood Bull Float

Draws excess water to surface. Bracket assembly kit included.

Laminated Wood Bull Float

Draws excess water to surface. Bracket assembly kit included.

POWER TROWELS

A simple 2x4 and a fresno may work fine when it comes to leveling and finishing a small residential slab, like a sidewalk or patio, but to place large driveways and sprawling commercial or industrial slabs, you’ll need equipment with a lot more speed and efficiency. For projects of this scale, contractors typically rely on power trowels, not only to improve productivity but also to ensure a smooth, level surface. Here’s an overview of your equipment options.

Walk-Behind Power Trowels

Walk-behind trowels are ideal for finishing driveways and small to mid-sized commercial or warehouse floors. In addition to being nearly effortless to operate, they give concrete surfaces a smooth, hard, durable finish. When buying a walk-behind trowel, the model you choose will primarily depend on how much surface area you need to cover. Walk-behind trowels come with blade diameters ranging from 24 to 48 inches. Smaller units are well-suited for finishing surface areas less than 1,000 square feet. They will also fit more easily through doorways and work around obstacles. Larger models are better suited for medium to large floors requiring greater speed and efficiency. With most units you can choose separate blades for floating and finishing or a combination blade that can perform both functions.

Most walk-behind trowels come in gas or electric-powered versions, allowing you to choose a machine that will work with the available power supply. Other features to look for include easy access to trowel blades, quick blade pitch adjustment, height-adjustable handles, ergonomic throttle control and optimal balance for smoother finishing. Top manufacturers include HoverTrowel, MQ Whiteman, Allen Engineering and EDCO.

Ride-On Trowels

For large concrete pours measuring over 6,000 square feet, a riding power trowel is practically a necessity for finishing the concrete before it sets. In addition to boosting productivity, ride-on trowels will also produce flatter finishes due to their weight. These machines come with twin blades ranging in diameter from 36 to 60 inches. You can also choose from overlapping and non-overlapping machines. Overlapping models have intersecting blades that are well-suited for trowel finishing, but you can’t use them for floating. Non-overlapping machines have a space between the rotors so you can mount float pans on them for initial finishing and switch over to trowel blades for final finishing. Smaller twin 36-inch-diameter ride-on trowels are easier to maneuver and provide adequate coverage for medium-sized floor slabs. For large floors requiring super-flat finishes, twin 60-inch-diameter ride-on machines are the best choice. In addition to size, look at the machine’s weight-to-power ratio, drive system (hydrostatic or mechanical), ease of pitch control, and blade accessibility.

Buying Tips

Power trowels and screeds can be big investments, with the cost of the most fully-equipped models often exceeding the price tag of a new car. Unless you do a lot of commercial work, consider saving money by purchasing a used model in good condition, either directly from the manufacturer or from a reputable dealer. Another option is to rent or lease the equipment.

Related Information

Constructing Commercial/Industrial Floors